Robin Longbottom examines how the discovery of coal led to a thriving village industry

THE village of Denholme is a largely 19th century development strung out along the old Keighley to Halifax turnpike road.

It extends from Manywells Heights, on the edge of Cullingworth, to Denholme Gate and in the late Medieval and Tudor period the area was a large, enclosed deer park. During the 17th century coal was discovered and small pits were opened to exploit it.

The village sits on top of the Lower Coal Measures which were laid down some 300 million years ago when the land was covered by tropical forest. The seam of coal in Denholme is known as the Halifax Hard Bed and contained extensive ‘balls’ of iron pyrites, also known as fool's gold. Since Tudor times pyrites had been processed to make copperas or green vitriol – iron (II) sulphate – which was once important in the textile industry. Copperas, now superseded by modern chemicals, was used as a mordant, or fixative, that prevented dye, particularly black dye, from fading or washing out.

One of the landowning families in the Denholme area were the Horsfalls and they began exploiting the coal seam in the 18th century. Timothy Horsfall, who died in 1811, expanded his business interests into cotton spinning at Goit Stock Mill in Cullingworth and his three sons – Jeremiah, William and Timothy – also went into textiles and traded as Wm Horsfall & Bros. However, they also continued the family interest in coal and sought to exploit the large quantities of pyrites.

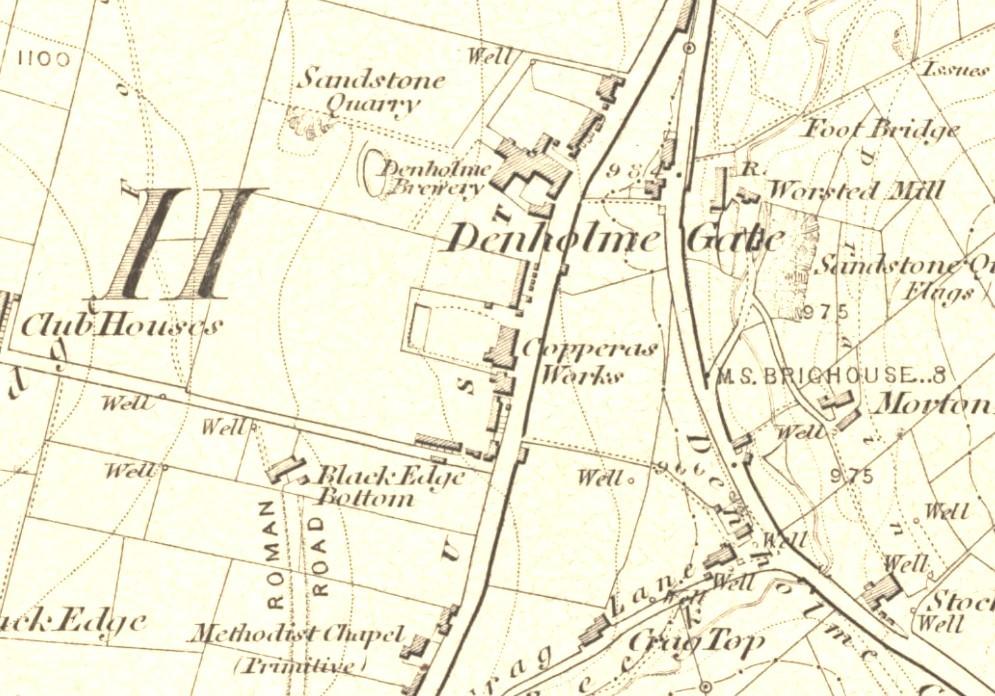

There were two copperas works in Denholme, both of which appear to have been owned by the Horsfall brothers. The largest one was at Denholme Gate and there was a smaller one just off Trough Lane near Manywells Heights. Both locations were probably dictated by the abundance of pyrites in the locality and the works at Denholme Gate were recorded as having the benefit of “a bed of pyrites measuring about 900 hundred square yards”. The area was also said to have pyrites of “excellent quality” that “may be had at an exceedingly low price”.

Both works consisted of a boiling house and cooling house. The process required the pyrites, together with a quantity of scrap iron, to be soaked outdoors in a tank for a considerable time to ‘ripen’. During this process a chemical reaction takes place, and the pyrites are oxydised. The solution was then transferred to the boiling house where it was put into large iron pots and heated until most of the water had evaporated. The concentrated liquor was then put into large lead-lined cooling tanks together with branches, or lengths of wood. Gradually crystals of copperas formed on the wood, and it was then removed from the tank, and the crystals were scraped off and packed into barrels ready for sale to the customer.

In 1834 Wm Horsfall & Bros put the Denholme Gate Works up for sale, with the alternative that it could be leased. Some years later it appears to have been occupied by a Mr William Pickles who was described as a copperas manufacturer of Denholme. It is not clear when the production of copperas finally ceased but in 1853 Bradford Corporation prepared a report to support their submission of a bill to Parliament to build Doe Park Reservoir at Denholme. They undertook of a survey of the watercourses flowing into the proposed reservoir and it stated that although refuse from the works had once found its way into the streams, the water had been analysed and no copperas was found. It was also understood that production by this time had ceased.

The old works at Denholme Gate have long since been demolished but the building that housed the works near Trough Lane still survives, although it has now been converted into two dwellings.

Comments: Our rules

We want our comments to be a lively and valuable part of our community - a place where readers can debate and engage with the most important local issues. The ability to comment on our stories is a privilege, not a right, however, and that privilege may be withdrawn if it is abused or misused.

Please report any comments that break our rules.

Read the rules hereLast Updated:

Report this comment Cancel